3rd YEAR INTERVENTION REPORT UNDER STED PROJECT (January, 2016 to January, 2017)

- The 3rd year Intervention program organised by the Organisation under the sponsorship of Dept of S & T has acquired more attention from the side of the public as compared to the 2nd year. This reflects the positive escalation of the awareness campaign and training programmes conducted by the Organisation.

- During the 2nd Intervention program, the organisation was able to support only 32 micro enterprises but this year we are looking forward to establishing and supporting atleast 50 new units of micro enterprises for income generation of the skilled.

- The 3rd Intervention programme “ Establishment of Micro Enterprises in Cane & Bamboo” was initiated at Lingsiphai village on 20th January, 2016. Chief Functionary and Secretary of SANGA was the resource person in the programme. We have interviewed stakeholders and shared their problems in setting up of a new enterprises to areas which had not been covered during the 2nd Intervention.

- On 15th March, 2016: Mobilisation and Establishment Programme was conducted at S.Kotlian village, where several skill artisans in cane & bamboo crafts gathered and these skilled artisans were motivated to set up enterprises with the present tools and equipments they have and the Organisation, with the help of DST will modernised their tools and equipments so that they can work with the locally available materials and commercialised their products to enhanced their daily income.

- These artisans are trained in primary training skills like the right season for cutting, splitting and extraction of bamboo to achieve the desire result in the products and to reduce later attacked by fungi and insects that deteriorate the finishing results of the products. Hand holding programmes will be held later after two months to artisans who have set up new micro enterprises with our initiatives and further awareness in market linkages will be provided.

- Cane and bamboo craft in Manipur is an integral part of their daily life. It is a traditional craft and has been practiced since time immemorial. Initially these natural fibres were used to make products of daily use. Every tribe and community makes materials of aesthetic yet functional use, their skills evolved over centuries of usage On 7th May, 2016: Skill Development Training in Cane & Bamboo Processing and Production under STED Project was again held here at Lingsiphai Village at the registered Office of SANGA. Skilled artisan like Mr Khupngaithang, Mr Pauminlian, Zuansamlian and other artisans have attended the programme. Since material like cane & bamboo are available in good quantities, the lack of designs and technical backup of these artisans are the drawback in marketing their products. Therefore they are trained in adopting new technique and design in the process of manufacturing and designing artworks, furniture and basketry. Also they were given awareness in different methods of finishing their products like smoking, varnishing, painting etc. base on the type of end-use and the specific products.

- The Trainer had emphasised that the Hill people are more into furniture, houses and its implements etc. but they need to focus on other various commercial items which are more in demand and needs to know the requirements of the consumers so as to expand the market circle of their products.

- 25th October, 2016: Market & Credit linkage awareness program and Final Intervention program under STED project was held at Kangvai for this fiscal year, where several villagers have attended the program and encourage them to adopt the modern techniques in Cane & Bamboo crafts for more profitable outcome in the production.

- By November, 2016, we are able to support and set up new 32 micro enterprises in and around Churachandpur District.

- As of now, we are able to established 74 micro enterprises (12 units in the 1st Year, 30 units in the 2nd Year and 32 units in the 3rd year). This year, our target was to achieve at least setting up of 50 units but due to unforeseen problems, we managed to set up only 32 new units.

- During these three years of STED project, we are able to set up 74 micro enterprises and we look forward to establish more units in the coming year.

Current year of operation & Year wise financial status:

| Year 1 | Year 2 | Year 3 | Year 4 | |

| Funds received | 9,60,000/- | 9,57,200/- | 10,58,000/- | |

| Funds utilized | Utilised | Utilised | Utilised |

Yearly achievements:

| S No | Parameter | Year 1 | Year 2 | Year 3 | Year 4 | Total | |

| I | Year wise details of No.

of training programs conducted |

12 | 13 | 13 | |||

| II | Year wise details of No.

of persons trained in different training programs |

50 | 109 | 107 | |||

| III | Year wise details of No.

of new micro- enterprise setup |

12 | 30 | 32 | |||

| IV | Year wise

details of No. of Jobs Generated |

Direct Jobs | 5 | 10 | 09 | ||

| Indirect Jobs | 7 | 15 | 17 | ||||

| V | Average monthly income per micro- enterprise | 5,000 | 10,000 | 10,000 | |||

| VI | Average job generation per micro- enterprise | 3-5 | 3-5 | 3-5 | |||

| VII | Average age of promoter per micro- enterprise | 35-51 | 35-51 | 35-51 | |||

| VIII | Average educational qualification of the promoter of micro- enterprise (10th,

12th, Graduate, PG) |

10th & 12th | 10th & 12th | 10th & 12th | |||

List 2-3 major S&T interventions (product/ process improvement/ product diversification/ value addition/ marketing linkage/ technology up gradation/ other) in both manufacturing and service oriented enterprises:

- Churachandpur is small yet hilly district, transportation and communication are slower than expected, as such, awareness and intervention conducted in regard to the projects were conducted with the same model as last year to areas where we have not covered. This year we have covered different regions of the district, yet the process adapted are of the same. We have classified both the S&T interventions in manufacturing and service oriented enterprises as under:

- a) Cutting and harvesting skills: Cane and bamboo are locally available in almost all areas of the district. However, knowledge on cutting and harvesting of the materials at the right season is vital. As such, trainees are imparted with the knowledge of the right season for cutting and techniques, intensity and number of bamboos to be harvested so as to avoid total depletion of the raw material and maintain ecological balance.

- b) Primary Training skills: If material are not harvested at the right season, finished products are prone to insect and fungal attack and easily get deteriorated. Therefore cutting, splitting and extraction of substances at the right season is vital so as to achieve reduction in starch content which reduces later attack by fungi and insects.

- c) Secondary processes of manufacturing and designing: Different finishing methods like smoking, varnishing, painting etc. based on the types of end-use on specific products are taught. Apart from tradition crafts, products like artwork, furniture, kitchen accessories, household used-items, etc. were also taught.

Innovative strategies adopted: These should target at affordable solutions suited to the given location, encouragement to social entrepreneurship, economic up-liftment etc.

- Use of ICT for market linkages: The internet and mobile phones are used for linking the producers with their customers. Mobile phone messaging and internet serve as means of communication between them and also provide a platform for engaging the two in creating a system of demand and supply. The producers are aware of the market pricing and demands while consumers are able to voice their feedback and order their choice of products.

- Technology upgradation: Trainees are made to use the internet for learning new skills and products. Various kinds of products are made available on the internet and the trainees can be able to access new and innovative products from all around the world. Trainees may also learn new methods of making products like preservation and designing methods etc.

Case studies: Pick up Two good case of micro enterprise for F.Y.2016-17 clearly specifying the type of Science and Technology intervention applied and the role of STED in nurturing the micro-enterprise (about a paragraph, how the intervention was sourced and how its benefits can be quantified in impact creation/value addition) .

Case I

- Mr Khupngaithang, 45years of age, has been involved in traditional basket making and other items as well. But the individual had been fetching a profit which is barely enough to run his business. He is now adopting the skills and methods imparted by Science and Technology Entrepreneurship development (STED) Project which enabled him to make a better quality and more profit from its products.

- i. Name: Mr Khupngaithang, Age: 45years, Educational background of Entrepreneur: 10+2

- ii. Address of Unit with Tel. No: Lingsiphai Village, Churachandpur, Manipur Phone:7627920378

- iii. Product/Services: Bamboo Baskets

- iv. Date of Start: 2010

- v. Total Investment in Rs.10,000/- to Rs 20,000/-

- vi. Source of funding: Own

- vii. Brief Background Mr Khupngaithang had been involved in making baskets and other bamboo products for some time with traditional tools and methods. This had not paid much dividend for the individual and the profit had been barely enough to keep him in business.

- viii. Role of STED project: Mr Khupngaithang has been imparted skill and technology training which not only make his production more efficient but also enable him to make better qualities.

- ix. Current status: Today he is adopting the skills he has learnt from the workshop and seminars organized under Science and Technology Entrepreneurship Development (STED) project to make better products.

- x. Future Plan: To make more profitable products and reach a wider market.

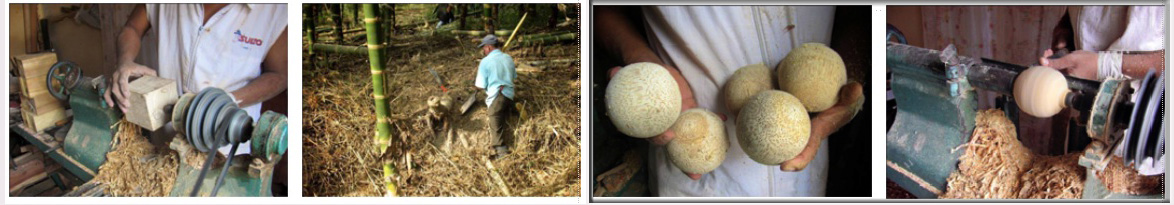

- Attach a good photograph of Product/Unit:

Case II

- i. Name: Mr Zuansamlian, Age: 34years, Educational background of Entrepreneur: 12th Passed

- ii. Address of Unit with Tel. No: Lingsiphai Village, Churachandpur, Manipur Phone: 9089940551

- iii. Product/Services: Bamboo Baskets, Mate etc.

- iv. Date of Start: 2011

- v. Total Investment in Rs.10,000/- to Rs 20,000/-

- vi. Source of funding: Own

- vii. Brief Background:Mr Zuansamlian had been involved in making baskets, mate and other bamboo products since 2011 with traditional tools and methods. This had not paid much dividend for the individual and the profit had been barely enough to keep him in business.

- viii. Role of STED project: Mr Zuansamlian has been imparted skill and technology training which not only make his production more efficient but also enable him to make profitable and better qualities products.

- ix. Current status: Today he is adopting the skills he has learnt from the workshop and seminars organized under Science and Technology Entrepreneurship Development (STED) project to make better products.

- x. Future Plan: To make more profitable products and reach a wider market.

- xi. Attach a good photograph of Product/Unit:

Highlight two challenges in micro-enterprise development chain (motivation, skilling, funding, marketing, technology etc.) specific to location and suggest solutions.

1) Upgradation of skill from traditional to modern technology. Due to lack of infrastructure and machine tools in the region, the people have been depending upon traditional methods and tools for production of goods. This method has not been able to meet the needs of both the manufacturer and the consumers. The materials are produced in low quantity and there is very low profit. Thus, there is a challenge to not only upgrade the methods of production but also to upgrade the tools and instruments for better production and efficiency. These problems can be solved through imparting skills and training to the entrepreneurs and helping them to acquire better tools and machinery to produce better quality of products.

2) Market linkages of finished products. There is a challenge of linking markets with finished products. If there is proper market linkages then the product manufacturers would be aware of price rate in the market, the present demand in the market that the consumers are looking for, and also establish a connection between the manufacturers and consumers. Market linkages would help in better and more efficient system of production. At present there is lack of linkage between the consumers and producers. The challenge of establishing efficient market linkages between the producers and consumers can be addressed through upgradation of ICT (Information and Communication Technology). Promotion of the use of better ICT, mobile messaging, internet and social media can be put to use to establish linkage between the producers and the consumers. Internet and social media use can also provide a platform for communication.

2ND YEAR INTERVENTION REPORT UNDER STED PROJECT (January, 2015 to December, 2015)

- The 2nd year Intervention program organised by the Organisation under the sponsorship of Dept of S & T has acquired more attention from the side of the public as compared to the 1st year. This reflects the positive escalation of the awareness campaign and training programmes conducted by the Organisation.

- During the first year, the organisation was able to support only 12 micro enterprises but this year we are looking forward to establishing and supporting atlease 50 new units of micro enterprises for income generation of the skilled.

- The first intervention on ” Establishment of Micro Enterprises in Cane & Bamboo” was initiated at Lingsiphai village on 15th January, 2015. Chief Functionary, SANGA was the resource person in the programme. We have interviewed stakeholders and shared their problems in setting up of a new enterprises.

- 2nd February, 2015: Mobilisation and Establishment Programme was conducted at Kangvai village, where several skill artisans gathered and these skill artisans in cane & bamboo crafts were motivated to set up enterprises with the present tools and equipments they have and the Organisation, with the help of DST will modernised their tools and equipments so that they can work with the locally available materials and commercialised their products.

- These artisans are trained in primary training skills like the right season for cutting, splitting and extraction of bamboo to achieve the desire result in the products and to reduce later attacked by fungi and insects that deteriorate the finishing results of the products. Hand holding programmes will be held later after two months to artisans who have set up new micro enterprises with our initiatives and further awareness in market linkages will be given to them.

- 5th March, 2015: Cane and bamboo craft in Manipur is an integral part of their daily life. It is a traditional craft and has been practiced from time immemorial. Initially these natural fibres were used to make products of daily use. Every tribe and community makes materials of aesthetic yet functional use, their skills evolved over centuries of usage

- Technology Intervention programme was held here at Lingsiphai Village at the registered Office of SANGA. Skilled artisan like Hauthang and Lalpianglian have attended the programme. Since material like cane & bamboo are available in good quantities, the lack of designs and technical backup of these artisans are the drawback in marketing their products. Therefore they are trained in adopting new technique and design in the process of manufacturing and designing artworks, furniture and basketry. Also they were given awareness in different methods of finishing their products like smoking, varnishing, painting etc. base on the type of end-use and the specific products.

- The Trainer had emphasised that the Hill people are more into furniture, houses and its implements etc. but they need to focus on other varioius commercial items which are more in demand and needs to know the requirements of the consumers so as to expand the market circle of their products.

- At the end of November, 2015, we are able to support and set up 30 micro enterprises in and around Churachandpur District. Our target was to achieve setting up of 50 units but due to unforeseen problems, we were below our targeted units. But our team is dedicated in setting up more units in the next intervention.

STED PROJECT REPORT FOR _2nd _YEAR OF IMPLEMENTATION

(In FY 2015-16, Details up to 31st December, 2015)

List 2-3 major S&T interventions (product/ process improvement/ product diversification/ value addition/ marketing linkage/ technology up gradation/ other) in both manufacturing and service oriented enterprises:

a) Cutting and harvesting skills. Raw materials like bamboo and cane are available in good quantity in the forest. However, there is lack of knowledge about the method of cutting and harvesting to benefit the producers while at the same time not depleting the resources and maintaining ecological balance. The trainees are imparted knowledge about the techniques of cutting, the right season for cutting, intensity and number of bamboos to be harvested or preserved. The trainees are taught scientific conservation skills and how to avoid total depletion of raw materials like bamboo.

b) Primary Training skills like cutting, splitting, extraction of gummy substances to achieve an even colour and reduction in starch content which reduces later attacks by fungi and insects. Without such modes of preservation the finished products are prone to fungi and insect attack and easily get deteriorated.

c) Secondary processes of manufacturing and designing different items and products like artwork, furniture, tiles, handicraft, kitchen accessories, houses, etc. Different finishing methods like smoking, varnishing, painting etc. based on the type of end-use and the specific product.

Innovative strategies adopted: These should target at affordable solutions suited to the given location, encouragement to social entrepreneurship, economic up-liftment etc.

- Use of ICT for market linkages. The internet and mobile phones are used for linking the producers with their customers. Mobile phone messaging and internet serve as means of communication between them and also provide a platform for engaging the two in creating a system of demand and supply. The producers are aware of the market pricing and demands while consumers are able to voice their feedback and order their choice of products.

- Technology upgradation: Trainees are made to use the internet for learning new skills and products. Various kinds of products are made available on the internet and the trainees can be able to access new and innovative products from all around the world. Trainees may also learn new methods of making products like preservation and designing methods etc.

Case studies: Pick up Two good case of micro enterprise for F.Y.2015-16 clearly specifying the type of Science and Technology intervention applied and the role of STED in nurturing the micro-enterprise (about a paragraph, how the intervention was sourced and how its benefits can be quantified in impact creation/value addition).

Case I

-

- Mr. Hauthang had been involved in making baskets and other bamboo products for some time with traditional tools and methods. This had not paid much dividend for the individual and the profit had been barely enough to keep him in business. Today he is adopting the skills he has learnt from the workshop and seminars organized under Science and Technology Entrepreneurship Development (STED) project. Mr Hauthang has been imparted skill and technology training which not only make his production more efficient but also enable him to make better qualities.

- i. Name: Mr Hauthang Age: 49yrs, Educational background of Entrepreneur: 12thPassed

- ii. Address of Unit with Tel. No. :Salem veng, Churachandpur, Manipur State. Phone : 9774049215

- iii. Product/Services:Bamboo Basket.

- iv. Date of Start :2009

- v. Total Investment in Rs.10,000/- to 20,000/-

- vi. Source of funding: Own

- vii. Brief Background

- Mr. Hauthang had been involved in making baskets and other bamboo products for some time with traditional tools and methods. This had not paid much dividend for the individual and the profit had been barely enough to keep him in business.

- viii. Role of STED project

Mr Hauthang has been imparted skill and technology training which not only make his production more efficient but also enable him to make better qualities.

-

- ix. Current status

- Today he is adopting the skills he has learnt from the workshop and seminars organized under Science and Technology Entrepreneurship Development (STED) project to make better products.

- x. Future Plan

To make more products and reach a wider market.

- xi. Attach a good photograph of Product/Unit

Case 2

-

- Mr. Lalpianglian has been making bamboo furnitures. He uses only traditional methods which puts him at a disadvantage in production. With the help of STED Project Seminar and training he has learnt new skills of production and innovative ideas. Using the internet he has been able to learn about new designs for making bamboo furnitures. He has also been able to establish linkage with the consumers with the help of mobile phone and internet.

- i. Name: Mr Lalpianglian Age: 39yrs, Educational background of Entrepreneur: 10th Passed

- ii. Address of Unit with Tel. No. Lingsiphai Village, Churachandpur, Manipur. Phone: 9862152990

- iii. Product/Services : Bamboo furniture & Basketry

- iv. Date of Start: 2010

- v. Total Investment in Rs.10,000/- to 15,000/-

- vi. Source of funding: Own

- vii. Brief Background

Mr. Lalpianglian had been involved in making bamboo furnitures with traditional tools and methods. He has faced problems in reaching a wider market.

-

- viii. Role of STED project

Mr Lalpianglian has been imparted skill and technology training which not only make his production more efficient but also enable him to reach a wider market.

-

- ix. Current status

Today he is adopting the skills he has learnt from the workshop and seminars organized under Science and Technology Entrepreneurship Development (STED) project to make better products.

-

- x. Future Plan

To acquire better tools and make better products.

- xi. Attach a good photograph of Product/Unit

9. Highlight two challenges in micro-enterprise development chain (motivation, skilling, funding, marketing, technology etc.) specific to location and suggest solutions.

1) Upgradation of skill from traditional to modern technology.

Due to lack of infrastructure and machine tools in the region, the people have been depending upon traditional methods and tools for production of goods. This method has not been able to meet the needs of both the manufacturer and the consumers. The materials are produced in low quantity and there is very low profit. At the same time the consumers are not able to easily acquire the goods. Thus, there is a challenge to not only upgrade the methods of production but also to upgrade the tools and instruments for better production and efficiency.

These problems can be solved through imparting skills and training to the entrepreneurs and also helping them to acquire better tools and machinery to produce better quality and quantity of products.

2) Market linkages of finished products.

There is a challenge of linking markets with finished products. If there is proper market linkages then the product manufacturers would be aware of price rate in the market, the present demand in the market that the consumers are looking for, and also establish a connection between the manufacturers and consumers. Market linkages would help in better and more efficient system of production. At present there is lack of linkage between the consumers and producers.

The challenge of establishing efficient market linkages between the producers and consumers can be addressed through upgradation of ICT (Information and Communication Technology). Promotion of the use of better ICT, mobile messaging, internet and social media can be put to use to establish linkage between the producers and the consumers. Internet and social media use can also provide a platform for communication.

- Detail report of STED Project implemented by SANGA 2015

The 1st intervention programme organized by the Organisation under the sponsorship of Dept. of S & T was Skill Development Training Programme which has paved a way of improvement in productivity among the informal sectors of local workers. Major localites, who based their livelihoods in bamboo and bamboo products are BPLs. There’s abundant raw materials but low-grade productions just to meet their daily needs. - These workers are given the motivation needed to establish micro enterprise by organising awareness campaign and training. The basic fundaments of setting up micro enterprises on bamboo and bamboo products, its viable business proposition in today’s market by upgrading the quality of their production.

- The S&T intervention will result in finer production, technology upgradation, choosing the right production, its market linkages and financial collaborator.

- The primary requirements of the local workers are Technology upgradation in produced items, marketing linkage and service oriented enterprises.

- Seminars and Symposium on technical development and upgradation for market linkages was conducted at Kangvai village(2014) and at Lingsiphai on 3rd February, 2015.

- Micro enterprises: To provide beneficiaries with Service and helping them generate sufficient income is the main target of the Organisation. However, the idea needs to be filtered and motivation with scientific technology and machinery is necessary. These beneficiaries are made aware of the basic fundaments of the Product, its processes, location of Plants, Financial collaborator and most importantly; choice of the product and its market linkages.

- 12 Micro enterprises are already set up in different villages, but the workers we are talking about here are people who are categorized under BPL and financial constraint is the major setback of this people, credit linkage is not possible for these enterprises as all bankers will firstly set their eyes on the enterprises’ financial viabilities. Therefore, Self Help Group is formed to help the enterprises in establishing credit linkage with the banker.

- As mentioned above, Setting up of Micro enterprise and providing them with credit linkage has a major setback with the financial collaborator as the banker would firstly set their eyes on their financial viabilities.

- We’ve initiated village to village mobilisation and formation of Self Help Group, these groups started saving which ever amount of money they could come up among themselves in the bank, that will reflect the enterprise’s financial viability

- So far, the Organisation is able to form 17 SHGs and opened saving accounts for each SHG in Manipur Rural Bank at Moirang.

- Members of the SHG were encouraged to contribute some amounts of money and start saving in their account so that credit linkage can be established.

- Conducting seminars and symposiums target to encourage existing enterprises, newly formed SHGs in social entrepreneurial skills by creating Social Entrepreneurial environment and setting up of more Bamboo processing units in the locality.

- The Organisation has been able to organized training programmes and hope to set up credit linkage with the local banks for beneficiaries in relate to Cane & Bamboo processing units.

- Credit linkage with Manipur Rural Bank, Moirang Branch has been initiated, as many as 17 saving bank accounts are opened for Bamboo Processing Units.

1. Type of enterprise

- A member of 3-5 nos per micro unit is being set up in different villages of Churachandpur District, Manipur. These units are set up for Bamboo and bamboo products in order to generate better income and provide more employment opportunities to the locals with locally available materials.

2. Total cost involved in setting up of unit/ enterprise:

- Basic formation of the unit/enterprises cost 5,000/- to 10,000/- depending on the geographical location of the unit.

Source of funding

- Presently we are solely depending on the assistance we’ve received from DST vide Sanction order no. No. 10/11/2013-NEB dated. 16.09.2013 & 18.12.2014.

- We have invited officials from locally available Nationalised Banks such as SBI, Manipur Rural Bank & HDFC with a possibility to set up credit linkage with these banks in future. We quoted the saying of one Mr. Inaotombi Singh, Manager, Manipur Rural Bank saying “All the units you’ve set up are still young and required proper transaction of money with the bank in order to set up the proper credit linkage” But in due course of time, the units will have satisfactory results in manufacturing and production, we aim to accomplish that level within this four years time.

4. Role of STED implementing organization in the launch of unit

- SANGA’s project; Establishment of micro enterprises in Cane & Bamboo processing and product development would not be made possible without the financial assistance of DST under STED project.

- Project selections are made only with Cane & Bamboo processing units, beneficiaries are given awareness of modernized skill development training and employment relevant courses in Cane & Bamboo. All financial expenses in setting up of micro enterprises are bored by the Orgnisation with the assistance received from the DST under STED project. Registration of established Units under MSME Act are under process and quality certification is also under process.

- All activities in regard to this project comes under the role of STED project as this project has been solely sponsored by STED project.

5. S&T intervention and value addition for the micro-enterprise:

- Intervention programme like ‘Skill Development Training Programme” has been organized under the project to improve and upgrade productivity of the local workers in the field of Cane & Bamboo, whose source of incomes are Bamboo and Bamboo products. We’ve conducted seminars and symposiums to encourage the existing enterprises and newly established enterprises. Earlier, Self Help Groups consisting of 7-15 members were formed and these groups were sub-divided into several units of 3-5 persons per unit/enterprise. The registration of these units under MSME Act is underway.

- Presently, 50 micro-enterprises has been set up under the support of S&T intervention.

6. Photograph of unit

Mr. Kh Kapa is a self trained entrepreneur who is amazingly skilled craftsmanship and manage his enterprise with locally available materials. He has a unique way of motivating other entrepreneurs in the field of Bamboo crafts.